Unlocking the Possibilities of 3D Prototyping with FDM and Resin Molds.

3D printing is one of the most revolutionary technologies of the 21st century, enabling rapid product development and prototyping. Fused Deposition Modeling (FDM) and Resin Molds are two of the most popular 3D printing technologies used to create high-quality prototypes. Both of these technologies offer designers and engineers the ability to create intricate designs and functional prototypes for a variety of industries.

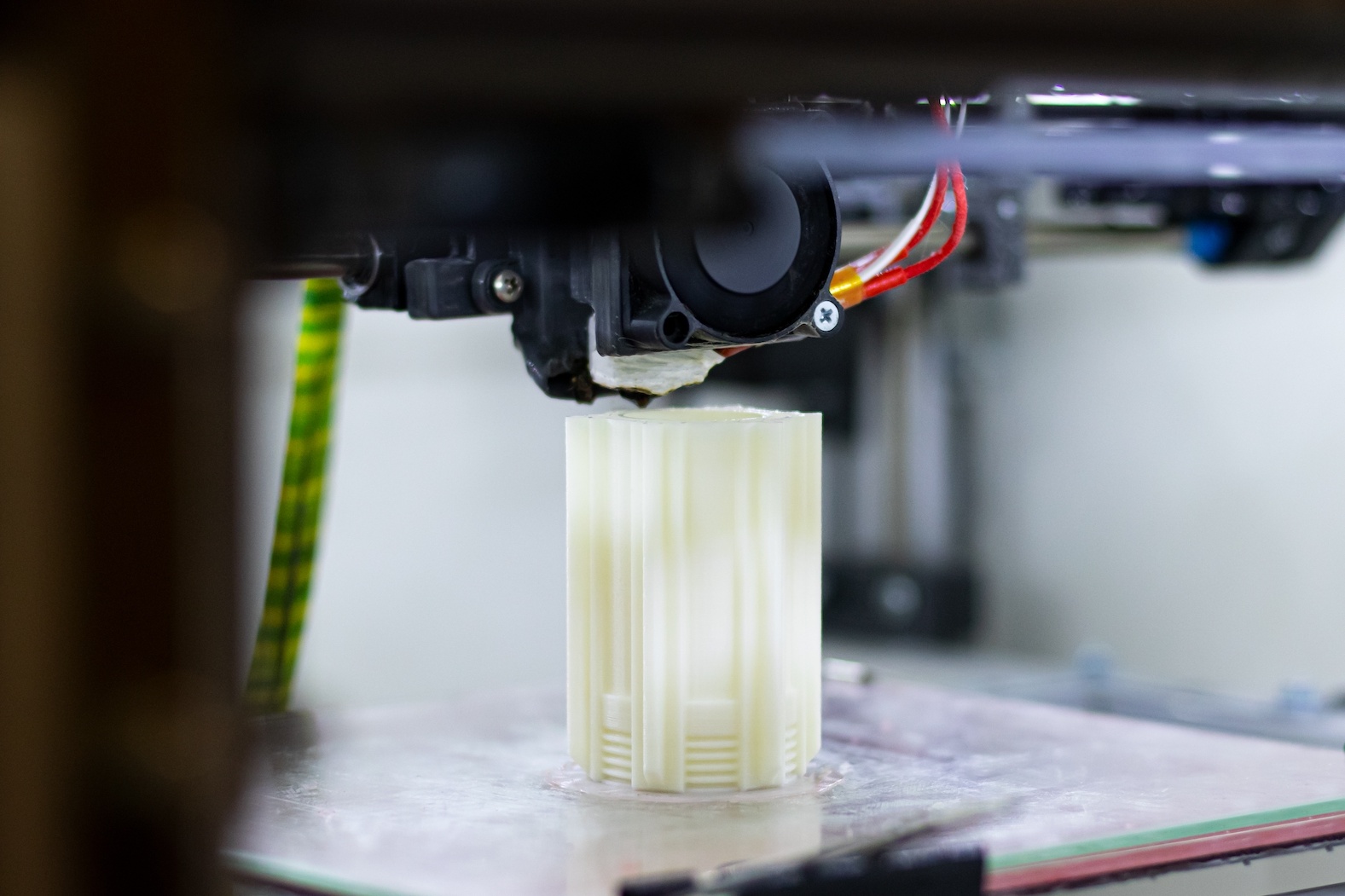

Fused Deposition Modeling (FDM) Technology

FDM is an extrusion-based additive manufacturing process that uses thermoplastic filaments. In this process, the heated filament is fed into an extruder head, which then deposits it layer-by-layer to build up the 3D design. This technology is ideal for producing parts with complex geometries and complex details. FDM also offers the flexibility to choose the right material for the specific application. Some of the most popular materials used in FDM are ABS, PLA, PETG, and Nylon.

Advantages of Fused Deposition Modeling (FDM)

-

- Material Options: FDM offers a wide range of material options that can be used to suit the specific application.

-

- Smoother Finish: FDM parts have a smoother surface finish than parts made using other 3D printing technologies.

-

- Ease of Use: FDM is relatively easy to use, as it requires less calibration and maintenance than other technologies.

-

- Precise Builds: FDM printing is capable of producing highly accurate and highly detailed 3D parts and prototypes.

Resin Molds

Resin molds are a form of stereo lithography, a light-based 3D printing technology used to create prototyping parts with highly detailed features and finishes. In this process, the liquid photopolymer resin is exposed to a UV laser beam, which hardens it layer-by-layer. Once the layer is complete, the model is then washed to remove the uncured material and the remaining layer is hardening.

Advantages of Resin Molds

-

- High Resolution: Resin molding is capable of producing parts with high-resolution details, including intricate geometries and fine details.

-

- High Quality Finish: This technology creates parts with an incredibly smooth surface finish that is ideal for high aesthetic applications.

-

- Faster Production Time: Resin molds can produce parts and prototypes faster than traditional 3D printing technologies.

-

- Cost-effective: Resin molds are more cost-effective than other 3D printing technologies for prototyping projects.

Both FDM and Resin molds are powerful 3D printing technologies that offer designers and engineers the ability to create detailed prototypes and intricate designs with greater speed and accuracy. By leveraging the power of both of these technologies, designers and engineers can quickly create functional and aesthetically pleasing products that are ready for the market or end-customer.